Filter Presses

We are Manufacturer, Supplier, Exporter of Filter Presses and our setup is situated in Pune, Maharashtra, India.

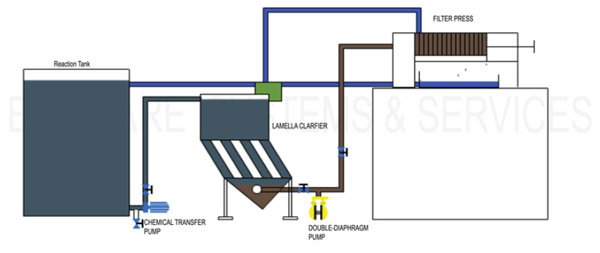

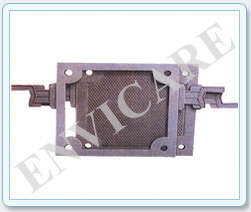

Envicare's - Sludge Handling SystemsEnvicare's one of the most popular sludge handling system is recessed type Filter Press with or without Electro Mechanical Plate Shifting Device : It is Mechanised Recessed Plates type Filter Press of SIZES varies from 355 mm x 355 mm to 1200 mmx1200 mm for 6-7 bar Filtration Pressure with and without hydraulic closing devices.

Moc of Skeleton : Cast Iron or Mild Steel.

Moc of Filter Element : Polypropylene Cast Iron, SS 304, SS 316

|

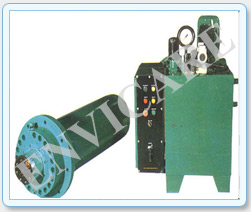

The system consists of pressure compensated motorized power pack having high pressure radial triplex plunger pump, solenoid operated direction control valve, pilot operated non-return valve, differential pressure switch, relief valve, pressure gauge and double acting hydraulic cylinder having 800 mm.stroke which closes and seals the filter plates pack automatically and returns the moving head to its open position by simply pressing a button.

Cylinder Tonnages Available :

40T, 50 T, 75 T, 100 T, 125 T, 150 T, 200 T, 250 T & 400 T

Filter Press with Capstan Closing Device

This type of closing Mechanism is recommended upto 355 mm x 355 mm size Filter Presss.A screw with hand-wheel is used for closing the pack of filter plates and for final tightning

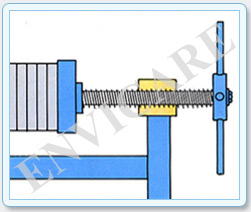

Filter Press with Ratchet Closing Device

The system consists of Ratchet Mechanism, Pinion and Gear Wheel. By applying a Ratchet lever to the pinion shaft the force is transmitted by small pinion to the larger gear-wheel which provides the final lightning on the plate pack.

The system consists of Ratchet Mechanism, Pinion and Gear Wheel. By applying a Ratchet lever to the pinion shaft the force is transmitted by small pinion to the larger gear-wheel which provides the final lightning on the plate pack.

- Filter Press

- Sludge Feed Pumps ( Optional)

- Filtration Cloth Set

- Hydraulic Closing Device (Optional)

- Sludge Collection Tray

- Poly Electrolyte dosing system (Optional)

- Compressed Air Line

- Civil Foundation/ Platform for mounting Sludge Feed

- Onsite Installation and Piping

- Wide range of sizes and configurations

- Optional expansion piece

- Automatic Operation

- Rugged Construction

- Extensive aftermarket services available

- DeWatering solution to most process flows

- Future expandability

- Reduced labor

- Long service life

- Convenience and reliability for you

- Chemicals : Basic,Orgnic & inorganic chemicals.

- Pharmaceuticals : Antibiotics Bulk Drugs, intermediates

- Pollution : Effluent Treatment Plants.

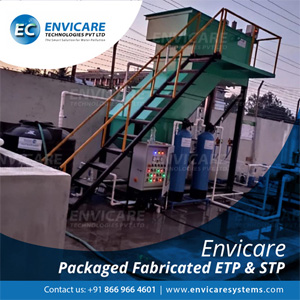

- ETP and STP

Above data is compulsory to understand your requirement and to proceed further.

- Effluent Treatment Plants ( ETP )

- Sewage Treatment Plants ( STP )

- Bag Filtration Systems

- Filter Presses

- Demineralised ( DM ) Water Treatment Plant

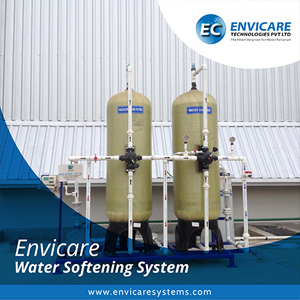

- Automatic Water Softener

- Oil Skimmers

- Reverse Osmosis ( RO ) Water Treatment Plant

- Water Purifiers

- Water Treatment Plants ( WTP )

- Rain Water Harvesting ( RWH )

- STP, ETP, WTP, WWTP AMC ( Annual Maintenance Contract ) Services

- Pollution Control Board ( PCB ) Compliances

- R&D Laboratory

- E-Microbes For Problematic STP and ETP New