Industrial Automatic / Manual Water Softeners

We are Manufacturer, Supplier, Exporter of Industrial Automatic / Manual Water Softeners and Our setup is situated in Pune, Maharashtra, India.

We provide our entire range across ALL OVER INDIA and all African countries

Water is considered 'Hard' when it has excessive levels of Calcium and Magnesium dissolved in it. The Borewell water and Well water are the main sources of hard water.

Envicare’s eSOFT Series - Water Softening Plants are designed to produce soft Water to suit for various applications. The soft water is of consistency quality with low residual hardness throughout the service cycle. The high synthetic resin is used to exchange Sodium ion with hardness forming Calcium and Magnesium ions.

After producing desired output, the resin is regenerated (Regeneration Process) with simple salt, Sodium Chloride (NaCl) solution after which unit will be again ready to deliver next batch. These units are easy to operate, no any skilled manpower requirement and almost maintenance free. The regeneration process can be placed Manual and Automatic.

These models are available to produce various capacities from 0.5 m3/hr to 25.0 m3/hr.( Please check the list as attached below). The difference between these models is in the capacity of the resin used for each model.

Water Softener Types:

• Resin based Softeners :

These most popular water softeners are utilising the Sodium based Resin as the main softening agent to remove the hardness from water. Available in Manual and Automatic regeneration mode. These systems works well at Hardness between 300 to 600 ppm. Above this limit it won’t work efficiently.

• Membrane based Softeners :

The RO ( Reverse Osmosis) membranes are used to remove the hardness from water. The removal of other unwanted minerals from water is the best aspects of these systems. It’s very good option when the Hardness of water is more 600 ppm

• Chemical based : Precipitating :

This is old aged technology for water softening. Washing soda and borax are the examples of precipitating Water softeners. These products upon reacting, forms insoluble precipitate with calcium and magnesium ions. The heavy sludge formation is the disadvantage of these system. This can be used in major Industrial applications.

- Anticorrosive Vessels - FRP/ MSEP- Long Life and less maintenance

- Manual and Automatic regeneration- Options to suit your budget

- User Friendly- Manual and Auto Regeneration– No need of any skilled manpower

- Remote Monitoring Feature available – No need of any skilled manpower

- Require Less space- As small as – 1M x 1M - No worry where to install

- Low power consumption almost NIL – Not to worry about heavy light bills

- Light weight – Easy to transport and shifting from one place to another

Advantages

- Health benefits like – Reduction in Hair Loss, Reduction in Soap and detergents

- No stains on the cloths and utensils.

- Reduction of scales in pipe and heating systems.

- Geysers and heating elements life increases.

- Low blow down for Boilers- Reduction in breakdown and maintenance cost

- Low scaling in Cooling towers.

- Great heat transfers - So reduction in electrical consumptions.

Application

- Society's , Bungalow's and Housing complexes

- Hotels and Restaurants

- IT Companies

- Solar Heating System - Feed Water

- Boiler, Cooling Tower Make-Up.

- Hospitals, Hotels, Laundries etc.

- Food processing.

- Chemical & textile mills.

- Power plants.

- Ice plant.

- Dyeing processes

- Pharmaceutical industries

Models

| SR No | SELECT THE MODEL | Resin Volume | SIZE ( DIA x HEIGHT in MM ) |

Min. FLOWRATE ( M3/Hr ) |

MOC | OBR* @ 500 PPM HARDNESS ( LIT ) |

| 1 | eSOFT - 15 | 15 | 200 x 450 | 0.50 | FRP | 1410 |

| 2 | eSOFT - 30 | 25 | 200 x 800 | 0.80 | FRP | 2350 |

| 3 | eSOFT - 50 | 50 | 250 x 1350 | 1.00 | FRP | 4700 |

| 4 | eSOFT - 80 | 75 | 300 x 1200 | 1.20 | FRP | 7050 |

| 5 | eSOFT - 100 | 100 | 325 x 1350 | 1.50 | FRP | 9400 |

| 6 | eSOFT - 140 | 125 | 350 x 1625 | 2.50 | FRP | 11750 |

| 7 | eSOFT - 180 | 175 | 400 x 1625 | 3.00 | FRP | 16450 |

| 8 | eSOFT - 250 | 240 | 450 x 1625 | 3.50 | FRP | 22560 |

| 9 | eSOFT - 300 | 290 | 525 x 1550 | 4.00 | FRP | 27260 |

| 10 | eSOFT - 440 | 425 | 600 x 1800 | 6.00 | FRP | 39950 |

| 11 | eSOFT - 710 | 690 | 750 x 1800 | 8.50 | FRP/MSRL | 64860 |

| 12 | eSOFT - 900 | 875 | 900 x 1800 | 12.00 | FRP/MSRL | 82250 |

| 13 | eSOFT -1330 | 1300 | 1050 x 1800 | 18.00 | FRP/MSRL | 122200 |

| 14 | eSOFT -2090 | 2000 | 1200 x 1800 | 25.00 | FRP/MSRL | 188000 |

OBR* is Output Between One Regeneration in Lit. In simple language after this quantity of water passed through the softener, It shall require the regeneration process to deliver the next batch of same quantity.

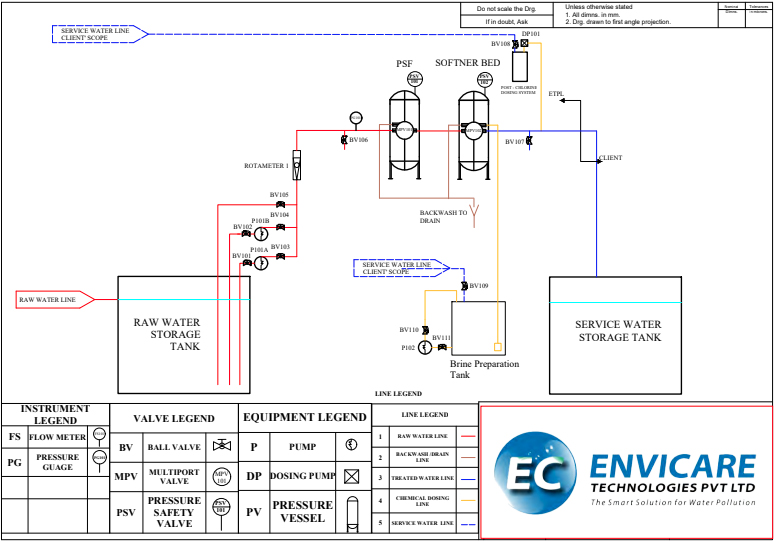

Flowsheet Diagram:

| Envicare - Water Softening Plant - Model eSoft | Flow Rate = | OBR - Lit | Comments (IF any) |

| Description | Type | Qty | |

| Raw Water Pump - CI | Centrifugal, Kirloskar/ Equi | 1 No | |

| Pressure Sand Filter (PSF) | Model: PSF Vessel - Tata Steel/ Equi | 1 Set | |

| Water Softener | Model: eSOFT Vessel - Tata Steel/ Equi, Resin Thermax/ Equi make | 1 Set | |

| Hypo Dosing System | 0-6 LPH Positive/ Equi | 1 Set | |

| Online Rotameter as Flow Meter | Aster/ Equi | 1 No | |

| UPVC Piping | Astral/ Equi | 1 Set | |

| Skid | MS Powder Coated | 1 No | |

| Hardness Test Kit | For 300 No of tests | 1 No | |

| Electrical Control Panel | Envicare | Optional | |

| Softner Automatic Regeneration | Auto Valves | Optional | |

| Online Digital Flow Meter | Flowmeter with Batcher | Optional |

Above data is compulsory to understand your requirement and to proceed further.

- Effluent Treatment Plants ( ETP )

- Sewage Treatment Plants ( STP )

- Bag Filtration Systems

- Filter Presses

- Demineralised ( DM ) Water Treatment Plant

- Automatic Water Softener

- Oil Skimmers

- Reverse Osmosis ( RO ) Water Treatment Plant

- Water Purifiers

- Water Treatment Plants ( WTP )

- Rain Water Harvesting ( RWH )

- STP, ETP, WTP, WWTP AMC ( Annual Maintenance Contract ) Services

- Pollution Control Board ( PCB ) Compliances

- R&D Laboratory

- E-Microbes For Problematic STP and ETP New